BREAKING NEWS – here is your cast trunnion “golden standard” quality from RAS47! Only 35 rds of Golden Tiger down the pipe! Pictures are from our member Dave K. You can’t make this up!!!

AK cast trunnion fail on RAS47 – Boom!

100 responses to “AK cast trunnion fail on RAS47 – Boom!”

-

Hmm…interesting. i also have a RAS47 and shot around 200 rounds at the range few days after i got it. Didn’t have any issue. Was using Wolf ammo. I’ll keep an eye out…

-

I have seen of this sort of stress failure occurring in some of the Serbian N-PAPs. The problem was traced to a single production run of trunnions, bolts, and rivets incorrectly tempered. However, those failed after hundreds of rounds down the pipe. If this rifle failed after only 25, they have a serious Quality Control issue in their manufacture.

Hopefully, this is a case similar to the N-PAPs and the problem has been corrected.

-

So I emailed Century, here is the conversation.

Heidi Bellizzi (Century Arms)

Oct 26, 13:00Steven

At this time we have no comment on what people are posting on the forums.

Thank you

Oct 25, 11:52

Name: Steven stout

Email:

Telephone:

Comment: So can some tell me why people are having problems with cast trunnions and bolt failure in your RAS47? I just bought one and have not shot it yet. Frankly I am afraid to shot it, I don’t want it blowing up in my face.-

I would take it to gunsmith and make him check headspacing on this gun.

-

-

It is a little disappointing they didn’t give you the time of day. Not surprising, but still disappointing. No chance of a refund from the place of purchase, Steve?

-

Nope

-

that no-comment reply from the company about the defect????….typical reply from a stupid idiot manager…..buy american????, hell no!!!!!!….they are going to get somebody killed…as long as the quality is remaining poor so the management can get their quarterly bonus????, fuck ’em…….buy romanian……..another example, look at the fucked up guns they made at kalashnikov usa in pennsylvania, an insult to russia!

-

-

-

A question for Rob and the guys about these RAS rifles. I JUST bought a RAS 47, and was very happy with the accuracy, but I never knew about the trunnions being cast until I found these pictures.

So do you guys recommend I get out of my RAS and into a different rifle? I wanted it for hard use work and now I can’t shake feeling it will eventually fail and let me down.

-

I would buy Definitive Arms DAKM4150N as my GO TO rifle for $999 and call it a day. But since you have RAS in your hands now, just keep using it and see how it works.

-

>I would spend a grand on an AK

LOLOLOLOLOLOLOLOLOLOLOLOLOLOL-

found the /k/ user.

-

-

-

-

Yeah, that DAKM has me staring hard at the piggy bank. Poor bastard has the sweats!

-

Rob, I cannot understand why any manufacturer would try to save a few pennies or dollars by putting lesser quality parts and hoping no one will notice. They must think we are stupid. They are wrong. I ALWAYS gladly pay more $ for cold hammer forged and chrome lined barrels. All of my ARs are built with Mil Spec or better parts. My AKs are Russian or Chinese. If the Russian military rifles have forged trunnions, there must be a reason. The lesson here is: If it works, don’t fuck with it, unless you can improve it! All we can do is educate people and vote with our wallets!

-

Thank you for posting this. I was tempted to buy a RAS 47, but because of a lack of information about the longevity on such a new rifle I decided not to trust it. I know I can trust an arsenal

-

We currently have two RAS 47’s as range guns. Each failed at about 3200 rounds. Guns were shot weekly and cleaned throughly and propery lubricated after each range session. I will be checking with the distributor and century about replacement. None of the weapons were ever dropped and or abused in any way.

Currently we have 14 long guns and 22 pistols for rent. Weapons are used mostly by soldiers for recreational shooting, and personal training. We only use factory ammunition, brown bear and silver bear for the AK’s and SKS’s and factory brass cased for the other weapons. At this point I would not recommend the RAS for any usage as the trunion failure can lead to firing out of battery and separation of the case and or possibly injuring the shooter.-

This is very sad to hear…

-

-

Although this is interesting, how many others have had their trunions crack and after how many rounds?

That is what I want to know. I have a brand new AR and it’s fit an finish pale in comparison to my RAS47

I just refuse to follow the ” don’t confuse me with the facts, I,ve made up my mind”

Once again, aside from this picture and report , how many cases have there been of cracked trunions?It,s a simple question.

Strong arguments require strong questions

-

Personally i have seen 3 so far. I have no idea how many is out there. All had broken internals in weakest points.

-

Mine just broke yesterday on my birthday … wish I would of seen this before I bought it a few years back. Haven’t even put that many rounds in it & the SAME EXACT thing happen. I wish I could send u a picture it looks exactly like your … what a horrible day. Now I’m gunna have to sell it I’m not even gunna worry about this piece of shit. I’m gunna get me a real Russian one 💯

-

-

-

I am a mechanical engineer/material scientist (and AK owner). I don’t work in the gun industry, and could give two shits about brand x vs brand z. From a technology and product development perspective, we live in a remarkable new world – every problem now has multiple great solutions, and the one you pick is more about you than the problem.

1) The photos show a part that has failed due to plastic deformation and ductile tearing. Its obviously not due to design. The AK trunnion design is as proven as any mechanical part designed in the history of mankind. There are many metallurgical reasons why this could have happened, but the most likely reasons are:

a) Lack of Heat Treatment or Poor Quality Control of the Heat Treatment process. Chro-moly steels, and most steels, can have their mechanical properties altered by heat treatment- from tough (and ductile) to strong (and brittle), simply by applying different heat treatment protocols. Parts are typically cast, machined, then heat treated (to save on tooling wear). This part might have been inadvertently left out of heat treat batch and reintroduced later, cooled improperly (too slowly), or any myriad of other possibilities. The solution to this kind of problem is largely administrative, and calls for some six sigma training and implementation.

b) Casting inclusions or voids. When casting, you can have voids and inclusions that weaken the mechanical properties of the parts. This can also happen with forgings (remember, all forgings were castings at one time). This is really doubtful, in my mind. Modern casting techniques are so refined, that significant voids and inclusions are rare.

c) The steel alloy metallurgy could have been defective. Alloys are mixtures of different elements, with different amounts of iron, carbon, chromium, molybdenum, vanadium, etc.. The base metal mixtures supplied to the manufacturer could have been off, which will affect the mechanical properties. This also seems very doubtful. Most steel mills have impeccable QC on their output, but whenever people are involved, mistakes can be made.2) There is no way any company could have this be a standard outcome of their manufacturing procedure and expect to survive. They would go bankrupt. This has to be an anomaly and/or a defect that rose out of a new manufacturing process, which is very common. I have been a part of many new product manufacturing operations, and the first ones off the line are always crap. Problems come up, you solve them. Hopefully you catch all the mistakes and fix them, but invariably shit happens and some leak thru. Problems get reported. Problems get fixed. I APPLAUD Century for having the guts to go down the path of developing a new mfg. line, producing a value oriented product, and keeping jobs in America.

Forgings vs. Castings.

Yes, if you asked me, would you like part x forged or cast (and it cost me the same) I would say FORGED. But, like all things in life, its not as simple as that. Yes, forgings are almost always “stronger” than castings (given equivalent starting metallurgy) but they are more expensive, and the degree to which they’re “stronger” is dependent on a variety of factors, which doesn’t even touch the question of how strong a part do you need?

a) Forgings, by definition, are castings that have been “hot worked” (in this application) with the objective to produce an even sized and aligned grain structure, remove casting imperfections and increase strength.

b) A forging is a forging is a forging. No. There is a wide range of how much forging a forged part actually receives. A part can be lightly forged, or heavily forged. If a forged part was $100 more and only 2% “stronger” is it worth it? $1000 more and 10 times stronger, is it worth it? Again, its a personal decision, is it worth it to you? But we need to ask the real question – how strong does a part need to be? What is the resulting strength to weight ratio required? Those are the real questions engineers deal with every day. Holding a bolt closed during a round firing. check. push ups by Rob Ski and his pals, check. Run over by a pick-up. check. You can record the actual stresses in psi that a part is subjected to in worst case scenarios (hot load, hanging from a tree, whatever) and say, “this part needs to have repetitive stresses no greater than X psi, no incident stress greater than Y psi, and a cycle life of Z”. Add safety factor, then you have a number to design to. ANYTHING MORE IS A WASTE OF MONEY, TIME and RESOURCES. No one talks numbers, but you can be assured that’s what Mikhail and his team did. They ran numbers. They chose forgings because that was the only way to make reliable, strong metal parts that met their design criteria in the 1940’s. It goes without saying that casting technology has come a long way in the last 70 years, so don’t throw the casting baby out with the bath water. I was recently at a car part mfg. in Stuttgart and they are doing amazing things with castings and hot isostatic presses (powder metallurgy). They are supplying Mercedes and Porsche with these parts. MANY parts that required forging and machining in the 40’s (or 80’s) are cast today. And a properly cast trunnion nowadays probably meets the design criteria just fine.What I dont know, and what I think would be cool, is for the Century engineers to engage their customers better and talk about these problems. I’m sure their lawyers would go nuts- but I bet there are engineers at Century who are chomping at the bit to talk about how they implemented new heat treatment processes, or how they had a problem with a subcontractor… but that’s probably not going to happen.

-

@ Forging vs Cast price of that specific part – price difference is…wait for it…less than $10, that’s from one source and other source told me that based on quantity they can drop it to as low as $2 in price difference…END OF DISCUSSION.

I’m just back from Shot Show. All major players going back to forging with exception of IO… -

I really think you hit the nail on the head here! I have worked with many QC people in the defense and aerospace industry (I was logistics/ supply chain security, then moved into social engineering cuz I’m a dick). They all point to problems like this with the engineers who do not have established criteria for performance, and also cutting corners for a few cents when they lose more money long term in reputation. Rep = Money! I have been looking for an AK that meets my performance requirements and stumbled upon AKOUL, which meets my expectations for what I want my weapon to perform as.

If Century lets its engineers interact with the end user, they will create a better product, and I think that your recommendation of a Six Sigma training and implementation is a great place to start. And….I see some money to be made for an industry specific SS Black Belt consulting group. LOL

But I’m going with DAKM 4150N or that DDI that Rob and Co. beat on. 🙂

-

Excellent information! Thank you for your expertise!

-

Excellent analysis. It is probably a stretch that Century has a significant engineering staff, since the design comes from a time honored bureau with millions of fielded examples to draw statistical data from. Machine parts drawings often get separated from special process documentation, and a special heat treating process may get truncated to say HT to Rockwell surface hardness XX but that does not speak to the effectivity of the depth of the heat treating or other critical design properties that don’t make it to the manufacturing drawings that third party manufacturers work with.

New tooling can be problematic even if historic process is followed. Such problems more often than not are related to a lack of systems engineering considerations regarding interaction of parts. The industry seems very competitive and these pressures drive cost decisions made by people who don’t understand the engineering consequences of short cuts. The industry needs to spend more engineering and design analysis dollars up front. It may save the need to spend legal dollars on the back end.

-

-

Very interesting stuff guys-thanks for the feedback.Im relatively new to AK and fascinated by them.Rob,you and the team are awesome keep up your great work.AK I have is IO AKM247.Quality seems very good -rivets straight,sights too. Fired two days ago thirty rounds.Weather-30 degrees,wind 20-30 and gusting 40 so was hard to really try a good zero process,I have put on the Meprolight night sight set and will provide feedback soon.Thanks guys.

-

Could you please post regular updates here? It would be interesting to see

-

-

Just got done shooting the first 360 rounds in my RAS47 , all tula , at home I compared the wear to my sagia and arsenal , seems to b doing great but my serial number in the 13000 will see

-

Mike, could you please post your updates here from time to time?

-

-

I just bought a RAS this past Christmas holiday, ran 1,000 rounds through it so far without issue but will definitely post here any failures that I encounter in the future if any.

Thanks for all you do Rob, much appreciated!

-

Please keep an eye on it. Thank you.

-

-

I have a RAS47 That I’ve put about 500 rounds through I’d post some pics. This being my first ak, Im not sure that this wear is normal, or not, but I do love the nitride finish on the gun. Tell me what you think. So far, I’ve seen 3 defects, some more nitpicks than others.

https://drive.google.com/folderview?id=0B2Zzk1FhrHZrODhGQWhLM1JDNUE&usp=sharing

1. The safety lever goes down a bit to far. (picking)

2. The lower hand-guard retainer is lose, but the hand-guard is still tight.

3. The rear sight slider cracked at some point, not on the range, and is slightly canted.

On issue 3 I contacted century arms, they said they would sent me a new one if I filled out a form of liability and and drivers license copy. Haven’t done it yet, as I don’t know how long they will retain my info for a fucking $3 part.

Love a response.-

From your pcis, i don’t see anything alarming. Is your bolt carrier marked with “x”?

-

There is a “C” on the piston, and what looks to be an “x” on the bottom of the carrier, under the bolt. Does that mean anything? Different production run?

-

X is good, that means it is from the newer heat treatment process.

-

Rob- Did your 5k round test use a rifle with newer heat treated parts (“X”) or old? Best,

-Abe -

It is X marked bolt carrier. You can see it on pics.

-

-

-

-

I’m looking at all the options for an entry level AK and it seems when I find one ( RAS-47, NPAP, WASR, exsetra…) there’s a story of how it blew up, bent it’s patrs, spontaneously combusted, or just flat out didn’t work.

Being on a budget I need a rifle that works, not a box of parcerized trot line ancor’s.

( plus, it would be nice to find something that takes cheaper mags than my Century VZ-58)

WASR rifles are great, but I think the cat is out of the bag on there reliability and I can’t find one in my area for under $750 out the door.

Any other budget AK rifles on the market that wont have any crazy issues and leave SOL.

OR…. has Century Arms quietly mended the tempering / casting issues and all is well and green lights on the RAS-47? if so, what Cerial number range should I look at?

Thank you , Watch your 6, and God bless.

-

Try to get OPAP or WASR

-

Thank you for the information, I’ll save a few more dollars and put it on a WASR.

If it all works out to get the rifle, I’m definitely going to take a Wild Hog with it.

just for kicks I might use the VZ-58 this year inside 100 yards.

If I get a hog, I’ll post some pics.

From what I’m seeing, 7.62×39 is rapidly becoming the new standard for (economical ) hog hunting in Texas.

-

The AK 47 seems to be a good fit for an all around rifle.

– Simaler to a 30-30 in nockdown but balistacly better.

– Well suited for shots on mediam sized wild game under 150 yards as seen in South Texas Mesquite / Central Texas Cedar Brush.

( Provided a side rail mount and a good scope.)

– Will do very well to defend the family if more than the old home defence 12g. pump is needed.

With AK quality and bullet technology geting better across the board, the AK platform seems to be takeing the role of not just a tactical weapon, but also as a rifle you can put meat on the table with and pass down to your kids when you get older.

And if the world goes crazy, its better suited to defend the homestead than a remington 700.

It just gets a little frustrating when guys can only aford to invest in one or two firearms and need there limited arsenale to be as “Swiss army knife” as posible to compinsate for limited funds to obtain purpose spisific tools.

So When the RAS-47 took a hit on the quality control and went questionable on service life, it was a sad day. I can take care of my tools and make them last a very long time, I just need them to not let me down.

I hope century arms can fix the problem and if posible “re-call” the bad run of rifles.

If I cant find a WASR or even more rare an OPAP, I will look for a RAS 47 rifle, carrier / trunion marked ‘X’ and just pray I got a good one. Onother avalibility problem is that there are a lot of RAS 47 rifles out there, even the BIG BOX chain stores are selling them now. People are holding on to there faithfule AK’s ( WASR, OPAP, ARSENAL, exsetra….) in this politicaly charged climate. (Given the outcome of this years elections.)

Maybe if we get lucky another former COM-BLOCK country will go the way of the CHECK’s and start running with a new modern rifle and start exporting there old AK parts kits by the boat load. ( Kind of saw a similar situation with the Iraqui contract Romanian built rifles.)

If anyone finds any evidence that the RAS-47 has been improved, PLEASE, post photos of stamping or engraving markings or a cirial number range to help everyone spot a good rifle and avouid a dud.

Thank you ‘Kurt W’ for your info input on the carrier markings and thank you Rob for your hard work in making the AK-4774 program posible.

To everyone reading, Thank you, watch your 6, and God bless.

-

Let’s hope that Century will continue to listen to people…that’s all we can hope for.

What serial numbers were problematic? And also what can guide me to finding out If my ras is gtg and has good heat treating ? Serial is RAS 47,0xx,5xx

-

I have no idea. It looks random.

-

You left the most important numbers of the serial number out..

-

That’s up to the owners – they don’t want to share it publicly.

-

*Update* I took the RAS-47 That I took pictures of out to the range again today, another 200 rounds. Had some issues with feeding, seemed like the bolt was short stroking a bit, not hitting the round with enough force to get in into the chamber; first time I had this problem. Later in the session, I had a issue where every couple rounds the trigger failed to reset at random. Figured out the problem when I got home and heard it rattling while I cleaned it. The screw that goes through my stock in to the back of the receiver had come loose, the nut on the other side of this screw was loose under the hammer, and caused the issues. It was a bitch to get it reseated, but with that done I lock-tighted it right. Seems like something century should watch out for, I had to take off the top cover at the range and fuck with the hammer to get it to reset, that could get your ass killed.

-

Thanks for your update.

-

Bought a ras blew up this weekend after grunion broke.

-

Trunnion

-

Are you ok? Hope you didn’t get hit with dust cover flying out or anything like this…could you please email me pics? ak74ski@comcast.net

-

-

I have a IO Inc. AKM247T that I got this past Christmas. Never heard of them and began doing research to find that no one seems to like them. Was worried about owning this rifle after all the negative things I had seen and read. Since I’ve had the rifle, I have put 390 rounds through it and have not had a single issue. Works every time I pull the trigger with slow deliberate target practice shots or random 30 round mag dumps. Only gripe I initially had was a canted FS/GB which I straightened myself and the bolt carrier jumping the rail and jamming when the recoil buffer was removed. Not too concerned with that right now since I don’t plan on removing the buffer permanently, but learned I could fix the issue with a surplus Bulgarian bolt carrier and recoil system if I choose to do so later. May do that eventually. I use Tapco Intrafuse 30 rd mags along with Fiocchi brass ammo, Wolf, Tul Ammo and Golden Tiger. Works great and have added a Magpul AK stock and pistol grip. Plan on painting it matte black with Aluma Hyde II when it warms up soon. My son in law just purchased a RAS 47 and looking over his rifle, it looks very well built. It has the X on the bolt carrier. I did notice on his rifle that if the dust cover is removed, when cycling the bolt carrier, it too will jump the rail and jam. A slight tap on the top of the bolt carrier will drop it back down allowing it to slam back forward. This is the first I have heard any other AK variant do this other than an IO Inc. Anyone else have this occur on their RAS? From what I understand, an AK should function without the dust cover if needed. I also tried the RAS recoil system and bolt carrier (with my IO bolt) in my IO AK and it cycled fine without the buffer. Weird.

-

My son in law said he called Century about the bolt carrier issue. Century told him as long as it functioned properly with the dust cover on, there was no issue and nothing they would do about it. That’s pretty lame……….!

I am interested to know what he is going to do about this rifle. As would anyone else that has purchased an RAS47. I had a conversation with century arms via email and they assured me that i shouldnt be concerned about it and that they have a number of RAS47s there that have 10k-15k rds no issues. Yet i see people with failing trunnions and BCGs. I am interested to know if century is going to deal with this issue should it happen to mine.

Hey Folks, I’ve got a 02xxxx run RAS and I was wondering what BCG you guys would recommend as a replacement. Also the carrier is marked with a T I just got this and I decided to mitigate the most common issues off the bat. Haha, before anyone says, “buy a different weapon”, I can’t afford one. Thanks guys.

I just purchased a week ago. 500 rounds, no issues. Inside looked good, no abnormal wear, a lot less than what I’ve seen in other peoples.

It’s marked on the lower side of receiver as “factory second” and #000380. No markings on bolt carrier, but was curious as to who else has RAS47 marked “factory second”.

rob just got a ras 47 feels good sn starts with sn 02 shot 200 rds bolt wear looks good do you think they just had a bad run

-

That’s possible. Quality control is equally important for making those rifles as grade of materials used. We will see how my rifle will look like at the end.

I picked up a AK63D underfolder milled reciver and called it a day.

-

Rob, I believe in the 63d video you stated it was the best rifle Century was making at this time.

I got one for a great deal while the price was right.

Being an election year and depending on who gets into office, prices on all AK’s could skyrocket late this year / into next year.

Shotguns, Bolt guns, & pistols are always going to be out there.

Tactical carbines could go on the endangered list if politics start to go down hill this next presidency.

Get a good AK soon before they get to expensive or out of stock because everyone wants to get one at the last minute before a bad bill gets passed or executive order hits the desk.

Stock up on mags to.Watch your 6, and God bless.

I just purchased a ras47 about a week ago. This was before reading all this. Looks good and I get to shoot it a week from today. The only issue is mine won’t accept my Romanian 75 round drum. It takes all my 30 round mags of various types. A little disappointed by this but fortunately I have an M+M M10 that does. Still kind of lame.

So I am new in the AK market. But I came across a used under foldIng WASR-10 and a new RAS47. I was leaning toward the RAS47 but now after reading all of this I don’t know. I also came across a c39v2 new. Little but higher in price then the WASR and RAS but was wanted some advice as to what I should do.

-

WASR is a good starting AK. Just try to find it with fixed stock…underfolder socks (stock). Or get it and then install adapter: http://shop.akoperatorsunionlocal4774.com/Under-Folder-AK-to-M4-Stock-Adapter-Under-Folder-M4-Stock-Adapter.htm

Just bought a Ras47 serial number RAS47036693 I didn’t see any (x) anywhere on the bolt carrier or (c)

I order a 640 round spam can from cheaper than dirt i will update if I see anything weird.

Just bought a RAS47 serial number RAS 470xxxxxxxx same as Josh no (X) or (C) anywhere, more than 500 round with normal ware. Maybe they fixed. I will keep posting .

I know this is kind of a late addition to the conversation. I just bought a used RAS-47. Despite what I had already known about them, I dived into the election hype and hysteria and dropped the duckets on a used RAS-47. I almost got a Yugo N-pap at my local gun store for $600.00 out the door, but I walked in as the previous customer was buying it. Sad day. Either way, I saw this guy on arms list selling his for $550. When I talked to him on the phone he said that his rifle ran flawlessly, and he put about 700 rounds through it. Only used the two Magpul mags that came with the rifle. I bought the rifle from him and took it home. The guy never cleaned it. Upon further inspection after giving it a deep cleaning I see some of the wear marks that Rob Ski had shown from his 5000 round torture test on the RAS-47, but these marks at the round count given to me by the previous owner do not show the same amount of wear Rob Ski’s rifle displayed after 500 rounds. This rifle to me is a very low Serial number RAS470061XX. My question is do we have a serial number range for which ones are fucking up? Also, where about on the bolt carrier is this X? I have found one on the bottom of the carrier next to the cut out for the locking lug. But its like scribbled in with electro pencil and doens’t look to me like a legitimate manufacturer stamping. If you guys want I can post some pictures of the wear surfaces.

Also, is it confirmed that replacing the bolt or carrier helps reduce the negative wear on the trunion? I read somewhere that Polish bolt’s are doing well in them. But I want some substantial evidence before I start slapping parts into my rifle. At the moment I haven’t even shot this thing yet. (Working in average of 60+ hours a week kills time to do anything)

Thanks!

-

Hi Andrew, i don’t have a SN range…but just recently i had a member with 30xxx serial number and his rifle was exhibiting pre mature wear only after 300 rds…

-

Well hopefully mine doesn’t go craptastic on me. Next weekend I’m taking it out and putting 300 rounds down the pipe. I’ll update and see if anything has gone terribly wrong.

Thanks to the election results, I am no longer paranoid. I’ll probably end up selling this, adding in a couple hundred more bucks, and pick myself up something nice. 🙂

-

Hey guys so I am having the exact same issue with a WSP build that I did through Arms of America out of Cripple Creek Colorado. I had a gunsmith look at it and he charged me 140 bucks just for reshaping and filing. He said that it was good to go, I took it to the range when I got it back and it is doing the same thing after 35 rounds. Is there any fix short of replacing the whole trunion?

Thanks

-

Tony, email me pics of the bolt and trunnion: ak74ski@comcast.net

I just got a new RAS47 in the 63,xxx serial number range, haven’t fired it yet. It has the faint “X” mark electro engraved under the carrier, and a large “T” stamped into the left side of the carrier. I wonder what the significance of this T mark is? Had I read about all the soft cast parts, I would not have purchased the RAS47. Oh well, it was an impulse buy (I am a die hard, long time, AR fan) and it will be fun to learn with. Just need to get some stain on that unfinished maple furniture.

-

Jim, because you got it now, just keep using it, but keep monitoring deformation of the bolt. At any signs of it, stop it and check head spacing first before using it again. All fails i have seen so far, all start with bolt deformations.

-

Thanks for the advice Rob Ski. Where exactly am I going to look for bolt deformation, on the lug and bearing surfaces I assume? I will try to find and order a set of go-no go gauges. SAAMI or CIP spec for the RAS47? Any specific gauge set recommendations?

-

I just bought a new RAS 47 haven’t shot it yet all I see is a x on it hope I got a good one.

-

You have newer one…these were heat treated to be more rigid. That’s all i have been told by Century…

i wish i would have read this before i bought mine. 500 rounds and the exact same thing occured to mine and i bought it 9/10/17. the left side of the trunion peeled back and the right side cracked apart !!

How are the MAK 90’s ? Cast or forged grunions and bolt/carriers?

-

Mak 90s trunnions were forged to my best knowledge

I have had my Ras47 for a few years now. I don’t get to shoot it much but have put at least 1k rounds through it maybe more and never had a problem. I do have a x on the bottom of my carrier even though my gun has a low s/n (9xx). Anyway today I took it out to go shooting an after about 20 rounds it started to jam so i just unloaded it an took it home to take a look the only thing that I could see is the trunnion was mushroomed out some and had a bur at the bottom it looked like the 3rd pic above not cracked anywhere I can see. I was wondering what to do. I don’t have alot of money to spend on it and would like to see what anyone would recommend. If I could fix it I would probably sell it but don’t want anyone who buys it to get hurt.

-

Update. Filled down the bur gun shot fine no jamming but i kept my eye on it an guess what it cracked on the opposite side. I looked close and I could tell this is some low quality cast with all the pitting in the metal. This has me a little pissed bought it out of state and got a bunch of accessories what a waste of money. This has left a bad taste in my mouth being my first ak. I’ll never buy century again. So now the question is what do I do with it hang it on the wall or sell it as a parts gun?

-

So I sent it back to the manufacturer to get fixed when ever I get it back I will sell it.

-

-

My RAS has an X in the carrier and that shit blew up well under 500 rounds

ANOTHER ONE!!

My RAS-47 just blew up well under 500 rounds. Cracked front trunnion like everyone else has had issues with.

I must say, I bought my RAS47 February of this year. I have an estimated 2100, 2300 round count on it. This was after viewing your videos. I must say i’m still in good shape in all of the areas (so far) no malfunctions, no warping, or chunks missing, trunnions all in great condition. I put around 300 round through it each use, and take it out about 3 to 4 times a month. You’ve far exceeded my personal test. For me there were no failures after submerging it in water, and rolling it around in dirt.

As I said before for me, I’ve had zero failures. Honestly I think I think I got lucky. I also have a newer model that was already outfitted in the zhukov magpul furniture. Thank you robski. I’ll keep you updated after I hit 5000 rounds.

I bought one of these in June 2016 from Buds after I had heard all the original hoopla and was excited to get it. It was the magpul version with serial # in the 25k. The fit and finish looks awesome and I love the gun aesthetically. . Stupid me didnt research it until after I had gotten it. So its now sat in my safe for three years and I am scared that it will blow up if I shoot it. I also dont want to sell it and put someone else in my position. I dont know what to do with the damn thing.

I have a ras 47 3,000 rounds and minimal wear. never had a malfunction works great ! I’ll check it out again in another 1,000 rounds but so far works great, also has an x on bolt carrier and c , the front and rear trunnions look brand new.

I’ve had my RAS47 for 5 years and put perhaps some were in between 2500 to 3400 steel cased ammo trough it no happy with the open sights since my eye sight is very awful so I’m getting a red dot put on it as soon as it arrives to the place I ordered it from I don’t know why every body is complaining about the RAS I shoot scrub barel grease up piston clean gas port put a little dab of grease on the hood and it shoots as smooth as budder I’m impatient on waiting on my red dot so I can be ALOT more precise on my hits

Hey Rob I enjoy your ak videos and my RAS47 is wonderful I love it I did put a red dot on it took to range did not like it I went to the eye doctor got new percription glasses since i’s past dew for some new glasses went back to the range with wolf red army and Tula and some silver bear and a little brown bear ran it all in my rifle at 100 yards open sights and after 3 and a half hours off fun it all grouped perdy good within a 12in by 12in bulls eye target I treat that gun like a machine I clean it and lub it up after every shoot I do and it hasn’t let me down after several thousands of round but my fun has to stop so I don’t shoot up all my ammo since ammo is very scarce now

-

Man, ammo situation is getting really sad…we will see what is going to happen in 2021…

Rob the ammo problem is I think ok for me now I’ve got several cases of silver bear bought and paid for put up ready to rock just in case but I hope every thing will be fine I’m going to get anoughter ak for my son but he will have to wait till he gets stronger cause he thinks the steal gun with a loaded mag is to heavy

Rob I love and respect the 7.62×39 round but for my next ak I’m thinking 5.45×39 ak74 because of how much more accurate and faster and devastating the wounds I’ve read about are

-

Dustin, I love 5.45×39. This is my favorite caliber AK. I just hope our amnmo supply won’t end…

I bought a C39V2 in 2019 and put it in my safe. Recently began shooting it and after approximately 250 rounds I had a case blow out. I had the headspace checked by a gunsmith. It was out of spec and the trunnion lug in the receiver on the right side was damaged. 250 rounds and now the rifle is useless, no more American made garbage for me.

For those of us who bought the Century Arms RAS47, and hearing that they were going to start using forged trunnions, do you know that dates/serial numbers when this change would have/did happen?

-

Hi, no, I have no idea. But CAI customer service should give you that info.

By all the negative commits on the RAS47 I guess I’m the lucky one and got a good well made one never has failed me yet let’s see if my memory serves me right I believe it’s miss fired only 3 rounds of the brown bear brand of ammo THATS IT 3 ROUNDS out of several thousands of rounds the only way I believe I can get my ak to blow up is if I fill it full of black powder insert fuze light it up and run like hell

Related Blogs

-

Best CAI AK”47″ – NEW milled MB47

-

King Of The Irons – Is Internet Wrong about AK47? Chinese Intervention!

-

Not my Grandpa’s AK47! AK SPR on the Budget – Whaaaaaaat?!

-

AK102 – Staying Alive?

-

5 Most Asked AK Questions!

-

AK vs SKS – which one is better?

-

Buying AK – My Selection Process!🔥

-

5 Reasons “AK47” Fails! 😮

-

My Way to Setup AK!

-

Poor “AK47” Accuracy – It’s Your Fault!

-

You must see it To Kill it!

-

5 Reasons Why You Need “AK47”!

-

Wow…just wow! Important Update!

-

BAD NEWS! No AK Videos for you!

-

AK Cheek Riser done in 60 seconds!

-

WTF Happened? 2022…

-

AK47 Secret Soviet KGB Method Exposed!

-

AK102 – Truly Awesome?!

-

Fixing AK Short(comings) – Cheap Way!

-

AK Setup – Do it right!

-

AK Guerilla Hacks – Don’t Aim! Just Hit it! Sling Hack!

-

AK Guerilla Gunsmithing 2! No Gas Tube and Rock!

-

AK guerilla Gunsmithing – Rubber Band & Toothpick!

-

Make AK Hitting Again! Simple steps to troubleshoot your AK!

-

BFT47 Last Shot – Could be yours now!

-

.308 AK Power – M77 Affordable import from Zastava!

-

If AK had a baby: Draco 9S

-

Stayin’ Alive – BFT47

-

SAFETY RECALL!!! BFT47, DON’T GET SPAMMED and MORE!

-

Polish AK 7.62×39 – Beryl 2k!

-

How I Mount Optics on AK

-

Better AK47 Recoil Management! Cost nothing!

-

BFT47 SWAMP DIVER!

-

AK Best Optic Yet?!

-

AK74 – Dead! 5.45×39 – Dead! All Dead! No! Actually, all is fine!

-

BFT47 – All Weather!

-

BFT47 – 500Yds AK? Century Arms Strikes Back!

-

5.56 AK M90 – Winter Adventures!

-

Shoot First! Buy Later!

-

Don’t Clean AK Much!

-

F@CK 2021 – So how was it for AK?

-

Zastava M90 OUT of GAS!

-

DPMS AK “Anvil” – Last Shot!

-

You Spin me Round, Like an AK Baby! – DPMS Black Panther AK takes a beating!

-

AK No Good, Hit Nothing – Troubleshooting AK Accuracy!

-

Waterboarding DPMS AK “Anvil”…

-

AK Community Hate – We hate on everyone and everything!

-

DPMS AK “Anvil” – Trigger No Reset…How to defeat Black Panther AK with one grain of sand…

-

5.56 Zastava M90 Swamp Choke – Not a Swamp Monster…

-

DPMS Black Panther AK – “Anvil” – What is this?

-

5.56 AK Kills it! Zastava M90 – steel ammo / mixed ammo and 500 Yards Dash!

-

Two AKs but Not the Same! Say What?

-

Jewish Claw Hammer with AK Heart – Galil Nail Driver DMR in 6.5 Creedmoor Evocatus Strategic

-

Russian Ammo Ban – 7 Days Later

-

5.56 AK To the Rescue! Zastava M90!

-

7.62×39 is Obsolete! Well, not so fast!

-

SKS – Yes or No?

-

SWISS ARMY AK in 7.62×51 – SG 751 SAPR with Mishaco!

-

LOOK AT ME, LOOK AT ME – This is YOUR AK NOW!

-

Before You Buy AK – Checklist! Must Watch!

-

Don’t Buy AK…Now.

-

Vintage Sniper World Championship 2021 – PARIS TN

-

AK 47/74 Caveman EOTech – Ooga Booga!

-

Kalashnikov USA KR 103 – Final Shot and Giveaway!

-

PSA AK 103 – Over Now!

-

New Import AK: Polish FB Radom Beryl in 7.62×39!

-

PSA AK74: Happy Easter!

-

Judged by 12 rounds – I SUCK WITH MY AK!

-

Kalashnikov USA KR103 – Hit me baby one more time!

-

PSA AK103 Drops 4k, takes a beating!

-

Winterizing your AK! Polar Vortex 2021!

-

2021 AK Import Miracle: FB Radom Mini Beryl

-

Chinese Dragunov Type 79 / 85 – History of The Red Dragon SVD!

-

PSA AK74 – Winter is Here!

-

Stalin’s Ghost Challenge: M41B – with Stalin voice over!

-

2020 was actually Good for AK?

-

Adidas and Soviets

-

PSA AK103 – Cold Sand. 3,000 Shots Fired!

-

Kalashnikov USA KR 103 – Boating Accident Survival Test Report

-

Snipers on the Eastern Front: Mosin Snipers!

-

PSA AK74 – Rust, rust, rust everywhere! Uboat Mission!

-

Kalashnikov USA KR 103 – Heat Stress!

-

AK74 – Riley’s Final Round!

-

Kalashnikov USA, KR103 is Here! AK103 Clone Wars in progress!

-

Saiga 5.45×39 – Evocatus Special! Wow!

-

PSA AK103 2k RDS Radioactive!

-

AK74 Reloaded – Riley Defense is Back!

-

2x AK103 = AK 206! Right?

-

PSA AK74 it is HERE!!!! Boom Shakalaka!!!

-

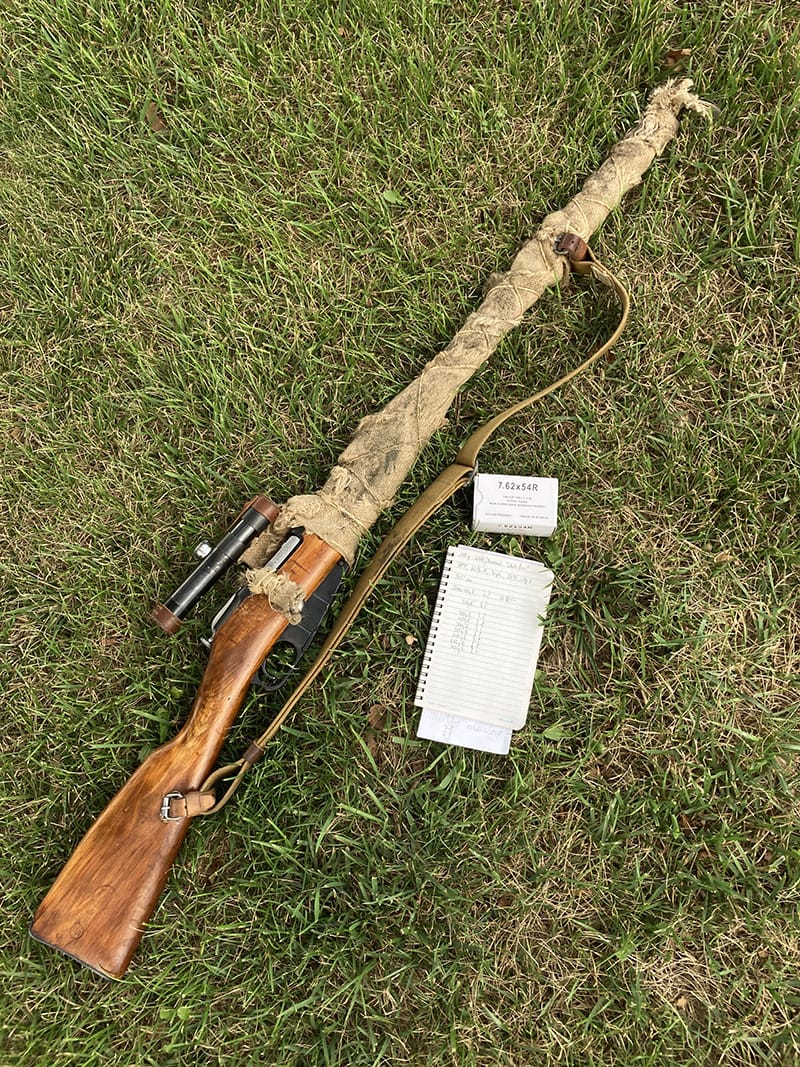

PU Mosin Sniper 148gr Wolf / Barnaul DOPE Card to 700yds

-

Best AK For Money Paid: Zastava ZPAP Z70 improved – 5000 Rds Final!

-

Bigger and Better – AK BootCamp Book – New edition is here!

-

Rifle Camo Wrap Tutorial! DIY section too!

-

PSA AK103 – 600yds Delivery! 1k Rds Range Report!

-

AK Record Breaker! ZPAP M70 (Improved) – 4,000 Rounds!

-

AK 103 from PSA – It’s here!

-

AK Iron Sights Giveaway!

-

Sniper SKS rifles?

-

Rapid Target Engagement with PSL 54 or SVD Type rifles

-

AK Iron Sight Upgrade – but does it HOLD ZERO?

-

New Bulgarian AK74 Magazines!

-

Serbian Import AK – Drop it! Get that Rivet Guy!

-

Natural Point of Aim – Ice Cream Baby!

-

ZPAP92 AK Pistol – Done in 2 Pieces! 5,000 Rounds Later!

-

10 AK Questions: Why and What?

-

Riley Defense AK – New Hope – Saharan Sand Storm!

-

Bulged trunnion AK: Zastava ZPAP (improved) 2000 Rounds Adventures!

-

AK 25 Yards Express Zero: how to zero your AK fast and be on target up to 300 Yards!

-

Shorty AK – ZPAP92 / Full of Sand!

-

6.5 Grenedel AK and 6.5 Creedmoor Galil!

-

Kalashni-Con 2020!

-

Riley Defense – Rivet, rivet Baby! 2500 Rounds later…

-

AK Optic – Ghost 2x! For 7.62×39 and 5.45×39 rifles!

-

New Improved Serbian ZPAP M70 AK: 1000 Rounds!

-

PSA AKE – Final Round!

-

Marksmanship and Honesty!

-

Riley Defense AK74 – Misfire!

-

PSL54 Sub MOA Rifle in hands of teenager… Accurizing it in 3 easy steps!

-

New Import AK – 2020 Miracle!

-

PTR32K 7.62×39 Pistol – 12″ Long!

-

New AK74 for USA!

-

Serbian Sniper Rifle: Zastava M91

-

Marksmanship Factory – Practical Shooter: Position Selection!

-

Enough with BS! Happy Easter 2020?

-

Kalashnikov USA – KP9 – Done!

-

Surviving The Apocalypse! Part 1

-

AK SIDE FOLDER POWER! Riley Defense 1500 Rds Update!

-

“Proven AK” – What is Proven AK? What makes it “Proven”?

-

PSA AK AKE STUNNER! Record Breaker!

-

Shorty AK: ZPAP 92 – 3,000 Shots Fired!

-

Corona Virus Special!

-

US made AK – why?

-

Triangle Side Folder AK from Riley Defense!

-

PSA AKE – Enhanced AK – Lights Out! 3k Rounds Update!

-

5.56 AK for You! ZPAP85 Pistol with Brace!

-

KALASHNIKOV USA KP9 – 4k!

-

PSA AKE AK – First Kill! 2000rds Update!

-

I hate new Palmetto State Armory AKE AK with FN Barrel!

-

AK Winter Shoot – Kalashni Con 2020!

-

5.56×45 AK from Serbia!

-

How to Zero “ComBlock” DMR / Sniper rifle with PSO 1 Scope! How to use PSO 1 scope!

-

Sub MOA PSL 54!

-

Hot Rod AK with Dong!

-

10″ AK Pistol Barrel Test while Suppressed: ZPAP 92 !

-

PTR 32 / 7.62×39 – Laser Gun!

-

Kalashnikov USA: 3k Reasons Why KP9 rocks!

-

SKS Suppressed – Do it yourself in 10 minutes!

-

Meridian AK: The Force Awakens – 4,000 Rds in Sand!

-

AK Pistol on Fire! ZPAP92 Rocks!

-

AK Master Mount – Awesome Optic Mount? Does it HOLD ZERO?

-

This is the Way! Poor Man’s Dragunov – PSL54!

-

5 Best AK Christmas Presents by Rob (2019)

-

American Vityaz – KUSA KP9 after 2000 Rounds!

-

Gun Control You Need: KNS Piston 2!

-

Happy Thanksgiving, AKOU is giving back!

-

Meridian AK Apocalypse: 3000 Rounds of Ninja Action!

-

Extreme Gun Control: KNS Adjustable AK Gas Piston! 😃

-

Kalashnikov USA KP9 – good and bad…😬

-

Bulgarian Invasion! AK47 Steel Mags!

-

AK Apocalypse Swamp, Meridian Defense: 2000 Rounds

-

ZPAP Rifle Giveaway!

-

VZ58: It must have been love, but it’s over now…5,000 Rds Later!

-

Kalashnikov USA KP9 / PSA AKV!

-

Zastava ZPAP AK: It’s Over Now! 5000 rds Later!

-

Apocalypse Now AK: 1000rds

-

Fly Like an Eagle! Zastava ZPAP 4,000rds Suppressed

-

What’s in the Box?!

-

Don’t Rest Mag on the Ground! Whaaaat?!

-

Sand Tornado Kill: Zastava ZPAP, 3000 Rounds Later

-

VZ58 after 4,000 Rounds later!

-

ZPAP AK: 2,000rds Suppressed! Deep Dive!

-

Slav Squat – how to shoot from squat!

-

Best AK Ammo? Barnaul Ammo Rocks!

-

VZ58: 3,000 Rounds Later – Don’t drop me now!

-

Zastava ZPAP AK: Suppressed 1,000 Rds Later!

-

Zastava USA ZPAP AK: Exorcist Wanted!

-

AK Suppressed! No magic, just physics!

-

Pistol AK – Puppy Fury! AKV – 4,000 Rds Later!

-

Zastava USA AK: ZPAP – Shots Fired!

-

“AK Kicked my Ass – Please help…”

-

VZ58 Czech’s Voodoo Magic!

-

Polish 80 PERCENT AKM RECEIVER! No FFL Required!

-

PSA AKV 9mm AK: 3,000 Rds Later!

-

Awesome AK rail!

-

PSA GF3 AK: 5,000 Rds Later!

-

Yugo AK Accessories – TDI Rail

-

PSA AKv 9mm AK – 2,000 Rds Later!

-

AK74 – I’m not Dead!

-

Ma! I got an AK47! Now what?!

-

CSA VZ58 – 1,000 Rounds Later!

-

PSA GF3 AK: 4,000 Rds Later!

-

SKS Paratrooper: To Bayonet or Not?!

-

VZ58 – Czech Hammer!

-

Century AK: VSKA – 5,000 Rds Later!

-

AK is not for you!

-

PSA AKV – 9mm AK: 1000 Rds Later!

-

WBP Fox AK: 5,000 Rds Later!

-

CZ Scorpion Evo: 5,000 rds later! Boomshakalaka!

-

Gun Control – Learn from Crazy Left

-

PSA AKv – 9mm AK: It starts now…

-

Palmetto State Armory Forged AK GF3: 3,000 Rds Later

-

Century VSKA AK: 4,500 Rds Later!

-

Yugo owners Unite!

-

WBP FOX AK: 4,500 Rds Later!

-

CZ Scorpion Evo3 S1: 4,000 Rds Later – WOW!

-

Palmetto State Armory, Forged AK GF3: 2,000 Rounds Later!

-

Century VSKA AK: 3,500 Rounds Later

-

Romanian Paratrooper AK: 5,000 Rds Later!

-

2019 Gun Control

-

Palmetto State Armory, Forged AK GF3: 1,000 Rounds Later

-

CZ Scorpion Evo3 S1: 3,000 Rounds Later!

-

AKOU 2018 Summary with Paul and Rob!

-

AK Headspacing: No Go/Go/Field..?

-

Palmetto State Armory: Forged AK – GF3 on Budget!!!

-

Century VSKA AK: 2,500 Rounds Later

-

Shots Fired: Deadly Accuracy of the Mosin PU Sniper Rifle! PU Sniper History!

-

Zastava M77 – Deadly Accurate!

Leave a Reply